Glass Bottle Production Technology

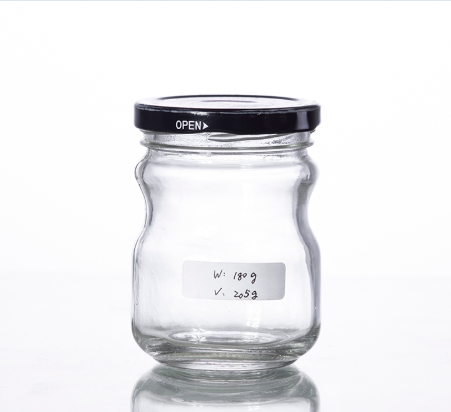

The production process of glass bottles such as Food Grade Glass Honey Jar includes: batching, melting, forming, annealing and other processes. Introduced as follows:

1. Ingredients, according to the designed material list, weigh the various raw materials and mix them evenly in a mixing machine. The main raw materials of glass are: quartz sand, limestone, feldspar, soda ash, boric acid and the like.

Second, the melting, the prepared raw materials are heated at a high temperature to form a uniform bubble-free glass liquid. This is a very complicated physical and chemical reaction process.

3. Forming is to convert the molten glass such as 8 oz Salad Dressing Bottle into a solid product having a fixed shape.

4. Annealing, the glass undergoes intense temperature changes and shape changes during the forming process, and this change leaves thermal stress in the glass.

In addition, some glass products can be rigidified in order to increase their strength. Including: physical rigidification (quenching), for thick glass, tabletop glass, car windshield, etc.; and chemical rigidification (ion exchange), for watch glass, aviation glass. The principle of stiffening is to generate compressive stress on the surface layer of the glass to increase its strength.

We are Sauce Glass Packaging Factory. If you have demand about our glass bottle, welcome to contact us.

评论

发表评论